Boiler with hot water cylinder system - Users Instructions

Exclusively written by Herts Boilers® (2024)

For small houses and flats, people use combi boilers. For a good hot water performance, and for big houses, we recommend a separate boiler (a system boiler or a heat only boiler) with a separate hot water storage cylinder, nowadays it is usually a mains water pressured one. This system is also called a megaflow system - sealed heating and unvented hot water cylinder.

For small houses and flats, people use combi boilers. For a good hot water performance, and for big houses, we recommend a separate boiler (a system boiler or a heat only boiler) with a separate hot water storage cylinder, nowadays it is usually a mains water pressured one. This system is also called a megaflow system - sealed heating and unvented hot water cylinder.

There are about 30% of households who are still using an open heating system with a vented hot water cylinder. The operation principles are the same. The heating is the same, but you don't get a good shower pressure and flow rate.

There are about 30% of households who are still using an open heating system with a vented hot water cylinder. The operation principles are the same. The heating is the same, but you don't get a good shower pressure and flow rate.

Users have plenty of boiler instructions, and plenty of programmer instructions etc, but we don't have a set of comprehensive instructions for such a whole system. After 15 years in heating industry, Herts Boilers® had recognised this need, and had exclusively written the following instructions.

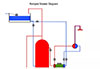

System diagram

The left is a schematic draw for a typical home heating and hot water system (non combi system). It has two channels, one for heating and another for hot water.

The left is a schematic draw for a typical home heating and hot water system (non combi system). It has two channels, one for heating and another for hot water.

The key component is a pair of motorised valves. A motorised valve is doing two things, first it is to open water flow way with heat energy from a boiler to either radiators or to hot water  cylinder, another action is to send an electrical signal to boiler for heat energy output on, if either heating or hot water is still required. If neither heating nor hot water is required, the boiler is on standby, and isn't consume any gas.

cylinder, another action is to send an electrical signal to boiler for heat energy output on, if either heating or hot water is still required. If neither heating nor hot water is required, the boiler is on standby, and isn't consume any gas.

Honeywell motorised valves are predominant in the UK, another popular one is Drayton.

The right is megaflow hydraulic scheme. We use a cylinder stat to shut off energy from the boiler if hot water has reached the setting temperature 60°C. It is the same as hot water control, if the room thermostat says the room temperature isn't still good enough, the boiler is keeping to produce heat to these radiators till a setting temperature is reached.

Programmer

A programmer is the starting point. Drayton and Honeywell are two mainstream makes for heating programmers.

A programmer is the starting point. Drayton and Honeywell are two mainstream makes for heating programmers.

This is a widely used Drayton LP722 (LP522 or LP822). A programmer is sending independent signals according to timing to both heating and hot water temperature stat. If a temperature stat isn't satisfied, the stat will send single to open correspondent motorised valve, then further to the boiler.

- Auto - three times of on and off per day (morning, lunch time and evening)

- Once - Morning on till evening off.

- 24 hours - all times on.

- Off - no action

Hot water on at the programmer - on signal to hot water cylinder stat - if hot water not hot enough - hot water motorised valve opens - on signal to boiler to run to heat hot water.

Heating on at the programmer - on signal to room thermostat - if room temperature not satisfied - heating motorised valve opens - on signal to boiler to run to heat rooms.

Hive and Nest

Nest (a Google company) and Hive (British Gas innovation) have the same functions of classic Honeywell or Drayton programmers, but they can be controlled by Apps on smartphones. With some algorithm and control strategy at behind, they are more energy efficient.

Nest (a Google company) and Hive (British Gas innovation) have the same functions of classic Honeywell or Drayton programmers, but they can be controlled by Apps on smartphones. With some algorithm and control strategy at behind, they are more energy efficient.

Programming

Overall in winter, about 50% gas consumption is used by heating, and 30% is used by hot water, and 20% used by cooking.

House insulation isn't often considered to be very good, so heating dose need timing. It still needs to programming heating on time to max energy efficiency. When not in home, or in sleep, you are better off to set the temperature down or heating totally off.

For hot water, it makes little difference now between a long time on or a short time on, in the view of energy saving. It mainly depends on how much hot water your family used. The heat loss by modern cylinders is very low now and can be ignored.

System pressure

An open heating system has no pressure gauge. It relies on a head tank in loft space which is called feed and expansion cistern.

If you can see a pressure gauge on your boiler, or a separate pressure gauge somewhere likely in your airing cupboard normally near the hot water cylinder, your system is sealed, and it needs to maintain a proper water pressure all times, normally between 1.2 bar to 1.6 bar when system is cold. The red needle is reference and black needle is the real reading.

If you can see a pressure gauge on your boiler, or a separate pressure gauge somewhere likely in your airing cupboard normally near the hot water cylinder, your system is sealed, and it needs to maintain a proper water pressure all times, normally between 1.2 bar to 1.6 bar when system is cold. The red needle is reference and black needle is the real reading.

With expansion vessel being good by a compression air charge, when heating is on and your radiators are getting hot, this system pressure can go up a bit for example over 2 bar but it should still be less than 3 bar.

It is a resident's responsibility to make an occasional system topping up. In heating industry it is commonly accepted that one can make a few times of top ups each year.

You can follow these steps for a system pressure topping up.

Immersion heater

On most of hot water cylinders, even they are primarily heated by gas boilers, there is still at least one electric immersion heater at each cylinder for backup purpose. Thus an immersion heater should be switched off if the boiler is working.

On most of hot water cylinders, even they are primarily heated by gas boilers, there is still at least one electric immersion heater at each cylinder for backup purpose. Thus an immersion heater should be switched off if the boiler is working.

First, gas is still much cheaper than electricity, secondly each immersion heater is about 3kW, much less powered than a gas boiler of 15kW or above.

This immersion heater is only for hot water backup, not for heating. If you use an immersion heater, you can leave it on all times, as there is a temperature stat built in to stop wasting energy if the setting temperature is reached.

This immersion heater is only for hot water backup, not for heating. If you use an immersion heater, you can leave it on all times, as there is a temperature stat built in to stop wasting energy if the setting temperature is reached.

It is not surprised that some immersion heaters are not connected to nearby electrical at day one by installers.

Boiler output temperature

Some boilers have two temperature output settings (knob dials or digital settings), one for heating and another for hot water. The heating one should always set to 65°C to 70°C. Most of hot water knobs on system boilers have no function.

Some boilers have two temperature output settings (knob dials or digital settings), one for heating and another for hot water. The heating one should always set to 65°C to 70°C. Most of hot water knobs on system boilers have no function.

The heating output on a system or heat only boiler is also for hot water storage cylinder, so the temperature setting must be higher than cylinder temperature of 60°C.

Cylinder setting temperature

Set the temperature of your hot water cylinder at 60°C (140°F) to prevent the growth of harmful bacteria such as Legionnaire. This is normally factory set you don't need adjust it.

Set the temperature of your hot water cylinder at 60°C (140°F) to prevent the growth of harmful bacteria such as Legionnaire. This is normally factory set you don't need adjust it.

Hot water at 60°C is burnt hot, you can't use its directly for shower etc, it is designed to mix up with another portion of cold water. So it is wrong to set hot water output temperature just at 40°C for direct use a hot water tap or  shower.

shower.

Modern unvented hot water cylinders have good insulation, so the heat loss is very min, as such it makes little difference between a long hot water on time compared with a short one on.

It takes less than half an hour for a cylinder to be heat up to a setting temperature 60°C, after that, the boiler will stop heating hot water till the temperature is down again, which is by using hot water not by cylinder body heat loss.

Shower pressure and booster pump

If you have a big water cistern in your loft space, and your water cylinder is either with a “red jacket” to keep warm, or with brown or green or blue form but not with a white surface, you have an vented hot water system and the shower pressure is likely lower. Some of these systems have already got shower booster pumps installed.

If you have a big water cistern in your loft space, and your water cylinder is either with a “red jacket” to keep warm, or with brown or green or blue form but not with a white surface, you have an vented hot water system and the shower pressure is likely lower. Some of these systems have already got shower booster pumps installed.

Radiators

As mentioned above, there should be a centralised heating room stat located at a typical and presentable location, not directly above a radiator, to sense the heating temperature. On most of radiators, they should be fitted with TRV valves, the bigger one with scale indicator is used to control each room temperatures, another smaller is a lock shield valve which is used to make system balance.

As mentioned above, there should be a centralised heating room stat located at a typical and presentable location, not directly above a radiator, to sense the heating temperature. On most of radiators, they should be fitted with TRV valves, the bigger one with scale indicator is used to control each room temperatures, another smaller is a lock shield valve which is used to make system balance.

It is always nature that all radiators are not coming on and hot at the same rate, some are getting hotter and quicker than others, we don't have a 100% balanced system, but if you have all radiators with all TRV valves, they will eventually come on for good, after hotter ones are shutting down by thermostatic valve and heating flow is forced to remote radiators.

If you do get one or two radiators not working, you might wish to do something following my another post.

Under floor heating (UFH)

Under floor heating is normally a separate collection of zones which is paralleled with radiators. As each loop for each UFH zone, it is normally consisted by a plastic 15mm pipe under the floor, the pipe is long so there is a high resistance, hence there is always an extra pump for UFH, also there is a mixing valve to low down and stabilise the temperature for UFH at 45°C (factory setting).

Under floor heating is normally a separate collection of zones which is paralleled with radiators. As each loop for each UFH zone, it is normally consisted by a plastic 15mm pipe under the floor, the pipe is long so there is a high resistance, hence there is always an extra pump for UFH, also there is a mixing valve to low down and stabilise the temperature for UFH at 45°C (factory setting).

These should be a motorised valve for UFH similar as to radiator control, but if you don't have a zone valve to shut off UFH when radiators are on, people are barely feeling any hot at UFH.

These should be a motorised valve for UFH similar as to radiator control, but if you don't have a zone valve to shut off UFH when radiators are on, people are barely feeling any hot at UFH.

Room stat

In our opinion, one centralised heating room stat is good and sufficient for most of households, plus a TRV on each radiator to balance each room temperatures. Having said that, we are not a biggest fan on a RF controlling smart TRV to each radiator.

A room stat shouldn't’t be placed right above a radiator, and a nearby radiator isn’t supposed to have TRV on it.

The right stat is so far the most popular room stat used in this country, Honeywell T6360B. It has just one fixed temperature, say 20°C, if you don't adjust it, it will stay like this forever. You can also switch on or off heating at the programmer to adjust room temperature.

The right stat is so far the most popular room stat used in this country, Honeywell T6360B. It has just one fixed temperature, say 20°C, if you don't adjust it, it will stay like this forever. You can also switch on or off heating at the programmer to adjust room temperature.

In digital era for heating there are no on and off concept anymore, just at a specific time and you set whatever temperature it is. To turn off heating completely, just lower its targeting temperature as low as possible, say 5°C, and the heating wouldn't be on.

In digital era for heating there are no on and off concept anymore, just at a specific time and you set whatever temperature it is. To turn off heating completely, just lower its targeting temperature as low as possible, say 5°C, and the heating wouldn't be on.

- 5pm to 10pm, family time 20°C

- 10pm to 6am, sleep time, set to 15°C

- 6am to 9am, otherwise the coldest time in the house so setting 20°C

- 9am to 5pm, away from home, set to 10°C

Holiday away

When you are going away for a three week holiday, always leave your heating system on. Image if you leave your car not run for a few weeks, can you re-start it again once you come back? It is the same!

Put heating temperature to a lower point, and leave hot water on, these will make boiler and pump etc to run briefly everyday.

(Last edited on 03/11/2024)

![]() Herts Boilers also maintain this blog site: https://www.boilerblog.co.uk/

Herts Boilers also maintain this blog site: https://www.boilerblog.co.uk/